The struggle is real — unless there’s a bona fide mail room in your office — packing and shipping is a serious pain in the a$$. Update: Our friends at the Stuff You Should Know podcast are speaking into my ear while I write this and their #sponsor Stamps.com has legit got me opening an account to avoid holiday Post Office Lines #postofficelinebegone.

But get this: the Geniuses in St. Paul flexed their adhesives muscles and developed a brilliant shipping & mailing product that abolishes the hunter gatherer ritual of finding essential supplies i.e. cardboard boxes, insulation, labels and more. Now, you just need a roll of… (drum roll pls)

Scotch™ Flex & Seal! Queue the fancy image & link….

I now tell everyone I know, plus those I don’t know – but I guess that’s part of the job – about Flex & Seal’s highly value adding properties. Namely, that it replaces all shipping materials needed, while costing less. WHOA. That second point needs further explanation, but let’s put a pin in that for a minute.

A single demonstration by fellow Motley Superwoman Kim and I was a Man of Mailing Mastery in Minutes. Similar to wrapping paper, Kim unrolled and cut off enough Flex & Seal to fully engulf Random Unmemorable Object. A lovely blue argyle design on the outside, mysterious gray on the inside…. Kim folded the gray to meet the gray and pressed them together. Trimming excess off the edges wasn’t just for appearances; she explained larger packaging = larger $ when you ship. Moments later, the final product was handed to me for inspection. Sufficient time had passed for the adhesive to meld the edges closed, fully and evenly, with no indications of an opening. I was surprised but skeptical.

Of course nothing from Scotch™ goes to market without teams of engineers attempting every feasible naturally occurring in transit, forced entry trick known to human kind. Nevertheless, I wrestled with the edges, corners and lip to find a way in. Eventually I got a hold, pulled hard, and breathed a sigh of disappointment, when only the top layer (see graphic 1) peeled off in my hands. Securely nestled within the mysterious gray inner cushioning, I could only make out the edges of said Random Unmemorable Object. Well guarded it remained, until scissors were brought in.

In the wild, packages are exposed to sorting machinery, “Throwers” – humans with no concern for fragility, conveyor belts, trucks, planes, trains and canvas bag carriers – all which tests a package’s durability. Bubble mailers are great for small items, but generally a few inches in thickness is all before you graduate to boxes, bubble wrap, peanuts and other insulation materials. You know the drill: fill the empty space with, well, filler, and try to keep your stuff from shaking around. Rarely is a box a perfect fit and perfect insulator in one; therein lies another problem. Bigger box (than you need?) means bigger shipping fees.

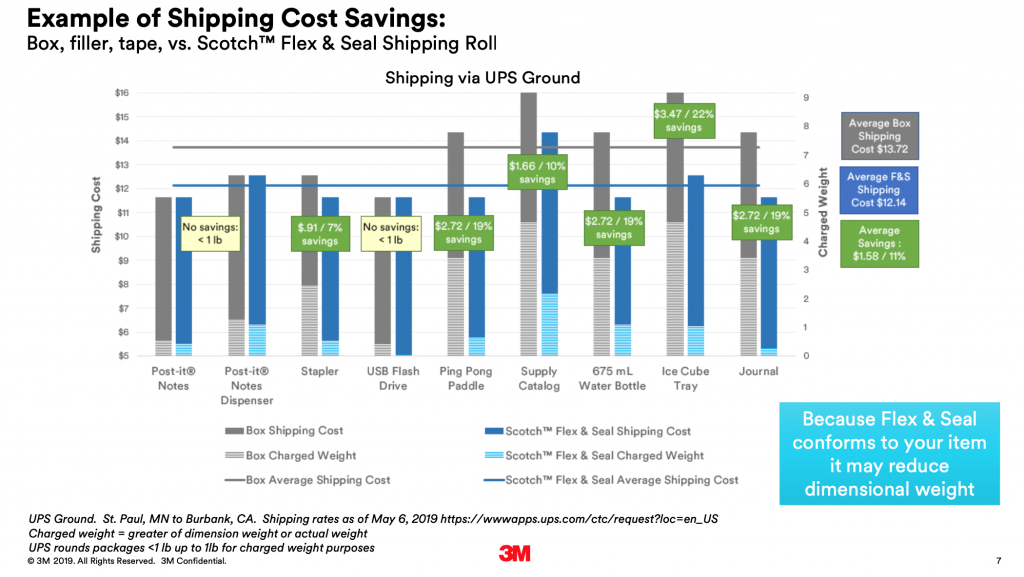

There were several studies done to analyze cost savings of box, filler & tape vs. Flex & Seal by our friends at 3M. Graphic 2 is a snapshot summary of the comparison – enough data for us nerds, but entirely possible to jump over if you’re the lay-man (more like lame-man!) Bottom line: packages >1lb were cheaper to ship with Flex & Seal.

What else? Flex & Seal is easier to store than boxes of multiple sizes, filler, etc. It’s waterproof, made in the USA and guaranteed by Scotch™. What more could you want? Well, read on my friends. Read on.

Further Reading

An article on sustainable packaging calls out Flex & Seal.

More to follow. Thanks for reading, friends! ~Tmg

Don’t be shy if you have something to say, friends!

By the way, a 10′ roll is about $10